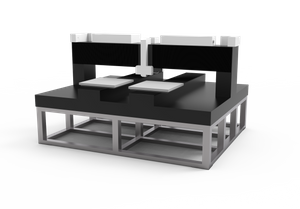

- HomeFull-automatic glass cutting system RZ-CU120S-AUTOHome » Applications » Laser Application » Laser Etching & Cutting » Full-automatic glass cutting system RZ-CU120S-AUTO

The system is applicable to the cutting of large-format electronic glass.

Glass incoming mode: bench incoming

Applicable product size: ≤ 1830mm * 2440mm, product thickness: 0.7mm-6mm

Working process: glass bench incoming material - automatic loading of the tipping machine - glass cleaning and drying - glass center positioning - laser cutting - laser splitting - automatic sorting of finished products (automatic waste removal of glass) - rear end transportation of finished products (automatic or manual insertion of the rack by the customer).

The system is applicable to the cutting of large-format electronic glass.

Glass incoming mode: bench incoming

Applicable product size: ≤ 1830mm * 2440mm, product thickness: 0.7mm-6mm

Working process: glass bench incoming material - automatic loading of the tipping machine - glass cleaning and drying - glass center positioning - laser cutting - laser splitting - automatic sorting of finished products (automatic waste removal of glass) - rear end transportation of finished products (automatic or manual insertion of the rack by the customer).

The applicable object parameters of the system are as follows:Machining object

Electronic glass

Product thickness

0.7mm-6mm

Product size

≤ 1830mm*2440mm

Dimensions after cutting

≥ 113mm*76mm (depending on the specific material)

For the applicable objects indicated in the table, the process capacity is shown in the following table:

Product positioning accuracy

≤±25μm

Spot diameter

≤ 3 μm

Repetitive machining accuracy

≤±3 μm

Edge collapse amount

≤ 0.1 mm

CCD alignment size

1830mm*2440mm

Positioning method

CCD automatic positioning

Cutting speed

≤100 mm/s (depending on the specific material)

Split velocity

≤100 mm/s (depending on the specific material)

The applicable object parameters of the system are as follows:Machining object

Electronic glass

Product thickness

0.7mm-6mm

Product size

≤ 1830mm*2440mm

Dimensions after cutting

≥ 113mm*76mm (depending on the specific material)

For the applicable objects indicated in the table, the process capacity is shown in the following table:

Product positioning accuracy

≤±25μm

Spot diameter

≤ 3 μm

Repetitive machining accuracy

≤±3 μm

Edge collapse amount

≤ 0.1 mm

CCD alignment size

1830mm*2440mm

Positioning method

CCD automatic positioning

Cutting speed

≤100 mm/s (depending on the specific material)

Split velocity

≤100 mm/s (depending on the specific material)

Related Products

OUR FOCUSCONTACT USThe core team of the company is composed of experienced academics and industry elites.FEATURED PRODUCTS

PRODUCT CATEGORY

NEWS & EVENTS

SUPPORT & DOWNLOAD