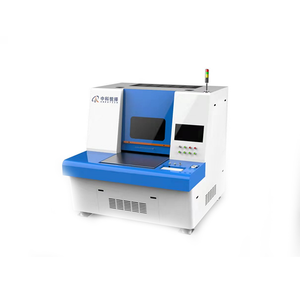

- HomeLaser Etching Machine RZ-8060DHome » Applications » Laser Application » Laser Etching & Cutting » Laser Etching Machine RZ-8060D

Equipment compatible product size: ≤ 800mm × 600 mm, applicable to etching of 21 inch wide materials and below capacitive touch screen visual area and wire area

The equipment configuration adopts a dual optical path system to realize high-speed synchronous etching of small and medium-sized touch screen lines with thin line width, which increases the etching efficiency of the equipment by 50%~80%.

The software control has the function of intelligent data blocking to meet the requirements of special-shaped typesetting, improve the use efficiency of materials, and reduce the loss of materials.

Double CCD automatic correction, various correction methods, ensure the accuracy of etching and meet customer needs;

Etching line pitch can reach below 20 microns, which can be etched with ultra-fine line width silver paste, meeting the customer's demand for narrow frame touch screen, etc

Equipment compatible product size: ≤ 800mm × 600 mm, applicable to etching of 21 inch wide materials and below capacitive touch screen visual area and wire area

The equipment configuration adopts a dual optical path system to realize high-speed synchronous etching of small and medium-sized touch screen lines with thin line width, which increases the etching efficiency of the equipment by 50%~80%.

The software control has the function of intelligent data blocking to meet the requirements of special-shaped typesetting, improve the use efficiency of materials, and reduce the loss of materials.

Double CCD automatic correction, various correction methods, ensure the accuracy of etching and meet customer needs;

Etching line pitch can reach below 20 microns, which can be etched with ultra-fine line width silver paste, meeting the customer's demand for narrow frame touch screen, etc

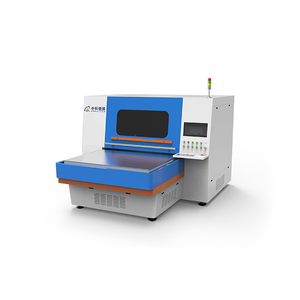

Processing materials

Silver paste, ITO, CNT, graphene, etc

Silver glue printing thickness/uniformity

8±2μm

Etching line width

30μm ~40μm(Depending on the processing material)

Linearity

≤±5μm

Integrated positioning accuracy

≤±10μm(Eliminate material printing errors)

Repetitive machining accuracy

≤±2μm

Splicing accuracy

≤10μm

Effective absorption format

800 mm×600 mm

CCD alignment size

800 mm×600 mm

Positioning method

Double CCD automatic positioning

Processing speed

≤3000 mm/s (Depending on specific materials)

Single PCS processing range

320 mm×160 mm

Processing materials

Silver paste, ITO, CNT, graphene, etc

Silver glue printing thickness/uniformity

8±2μm

Etching line width

30μm ~40μm(Depending on the processing material)

Linearity

≤±5μm

Integrated positioning accuracy

≤±10μm(Eliminate material printing errors)

Repetitive machining accuracy

≤±2μm

Splicing accuracy

≤10μm

Effective absorption format

800 mm×600 mm

CCD alignment size

800 mm×600 mm

Positioning method

Double CCD automatic positioning

Processing speed

≤3000 mm/s (Depending on specific materials)

Single PCS processing range

320 mm×160 mm

OUR FOCUSCONTACT USThe core team of the company is composed of experienced academics and industry elites.FEATURED PRODUCTS

PRODUCT CATEGORY

NEWS & EVENTS

SUPPORT & DOWNLOAD