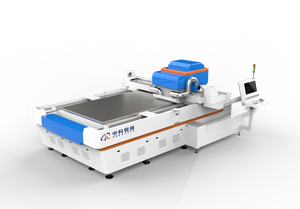

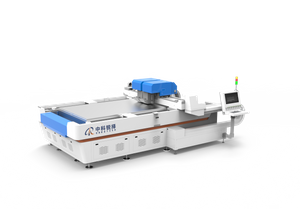

- HomeLaser Etching Machine RZ-UV86DHome » Applications » Laser Application » Laser Etching & Cutting » Laser Etching Machine RZ-UV86D

The equipment is easy to use, operate and maintain, beautiful in appearance, compact in structure, stable and reliable in operation, and excellent in after-sales service.

Compatible product size: 1320mm * 2190mm;

The equipment is configured with A+B dual optical path system, set A is equipped with infrared laser specially used for silver slurry line etching, set B is equipped with ultraviolet laser specially used for visible area line etching, which can realize high-speed synchronous etching of 86 inch touch screen line with thin line width, and is specially used for excitation light etching processing of double-sided coating materials..

Positioning mode: CCD correction system automatically calculates the position deviation of film material.

The equipment is easy to use, operate and maintain, beautiful in appearance, compact in structure, stable and reliable in operation, and excellent in after-sales service.

Compatible product size: 1320mm * 2190mm;

The equipment is configured with A+B dual optical path system, set A is equipped with infrared laser specially used for silver slurry line etching, set B is equipped with ultraviolet laser specially used for visible area line etching, which can realize high-speed synchronous etching of 86 inch touch screen line with thin line width, and is specially used for excitation light etching processing of double-sided coating materials..

Positioning mode: CCD correction system automatically calculates the position deviation of film material.

Processing materials

Silver paste, ITO, CNT, graphene, etc

Silver glue printing thickness/uniformity

8±2μm

Etching line width

30μm ~40μm(Silver Paste)

15μm ~22μm(ITO)

Linearity

≤±5μm

Integrated positioning accuracy

≤±10μm(Eliminate material printing errors)

Repetitive machining accuracy

≤±2μm

Splicing accuracy

≤10μm

Effective absorption format

1320 mm×2190 mm

CCD alignment size

1320 mm×2190 mm

Positioning method

Double CCD automatic positioning

Processing speed

≤8000 mm/s (Depending on specific materials)

Single PCS processing range

150 mm×150 mm

Processing materials

Silver paste, ITO, CNT, graphene, etc

Silver glue printing thickness/uniformity

8±2μm

Etching line width

30μm ~40μm(Silver Paste)

15μm ~22μm(ITO)

Linearity

≤±5μm

Integrated positioning accuracy

≤±10μm(Eliminate material printing errors)

Repetitive machining accuracy

≤±2μm

Splicing accuracy

≤10μm

Effective absorption format

1320 mm×2190 mm

CCD alignment size

1320 mm×2190 mm

Positioning method

Double CCD automatic positioning

Processing speed

≤8000 mm/s (Depending on specific materials)

Single PCS processing range

150 mm×150 mm

OUR FOCUSCONTACT USThe core team of the company is composed of experienced academics and industry elites.FEATURED PRODUCTS

PRODUCT CATEGORY

NEWS & EVENTS

SUPPORT & DOWNLOAD